Product

KV-10 Viscometer Bath - 84300-0

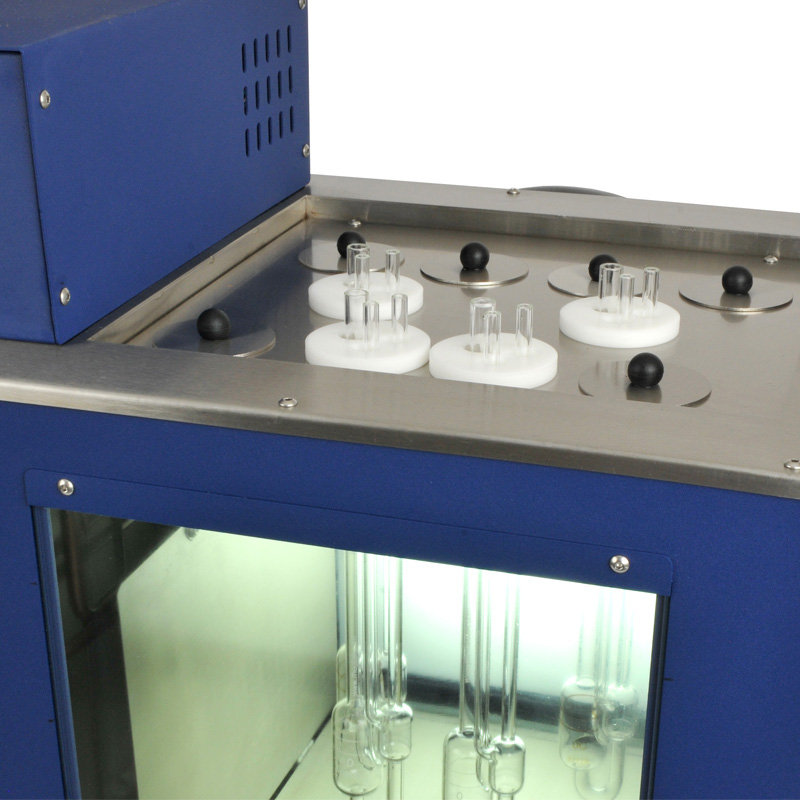

The Seta KV-10 Viscometer Bath gives users a high quality, robust solution for kinematic viscosity determinations in the temperature range of Ambient to 150 °C. The KV-10 precisely maintains the temperature of up to 10 viscometer tubes, which are used to measure the viscosity of liquid petroleum products. Ultra precision temperature stability and uniformity is achieved with an integrated heating and stirring system. The bath offers high stability of ±0.02 up to and including 100 °C, ±0.03 above 100 °C.

All internal components are made of stainless steel construction to ensure long term durability. The large 40 Litre capacity ensures minimum temperature recovery time after loading the bath, improving sample throughput. Each aperture has a cover to minimise heat loss when not in use.

The bath is equipped with a toughened glass front window, easily accessible drain valve, integral back lighting, top plate and provision for reference thermometers and attachments. LEDs illuminate the bath so that the viscometer tubes can be viewed more easily.

Features

- Temperature range Ambient to 150 °C

- Stability ±0.02 up to and including 100 °C, ±0.03 above 100 °C

- Accommodates up to 10 viscometer tubes

- Digital display with 0.01 °C resolution

- Oil, silicone fluid or water filled

- Low liquid level and over temperature protection

- Integral back lighting

- Double wall glass front panel reduces heat loss

Information

Details

Kinematic ViscosityKinematic viscosity is a key property for fuels and lubricants. Kinematic viscosity is determined by measuring the time it takes for a sample to flow through a glass capillary viscometer at a known constant temperature. Kinematic viscosity is extremely temperature sensitive and as such an accurate stable temperature controlled bath is essential.

Most fuel specifications include viscosity at a specified temperature. Viscosity in fuels determines how well the fuel will pump to the engines. For lubricants, kinematic viscosity determines the ability of a lubricating oil to create and maintain lubrication films between moving parts. Poor lubricant performance causes wear and overheating. Kinematic viscosity measurements enable the calculation of viscosity index. Viscosity index is an important parameter which describes the relationship between viscosity and temperature for a given lubricant.

Supplied with: 10 covers for test wells, mains lead and instruction manual.

Please note: excludes Viscometer tubes, these must be purchased as an additional accessory.

Details

| BS 188 | Methods for determination of the viscosity of liquids |

|---|---|

| ISO 3104 | Kinematic Viscosity of Transparent and Opaque Liquids and the Calculation of Dynamic Viscosity |

| ASTM D446 | Standard specifications and operating instructions for glass capillary kinematic viscometers |

| ASTM D2170 | Kinematic Viscosity of Bitumens (Asphalts) |

| DIN EN ISO 3104 | Methods of test for petroleum and its products. Transparent and opaque liquids. Determination of kinematic viscosity and calculation of dynamic viscosity |

| DIN 51 562 | Determination of Kinematic Viscosity using Ubbelohde Viscometers, capillary Viscometers |

| IP 71 | Determination of kinematic viscosity |

| ASTM D445 | Method for Kinematic Viscosity of Transparent and Opaque Liquids |

| ASTM D2270 | Standard Practice for Calculating Viscosity Index From Kinematic Viscosity at 40 and 100°C |

| BS 2000-71-2 & ISO 3105 | Methods of test for petroleum and its products. Kinematic viscosity. Specifications and operating instructions for glass capillary kinematic viscometers. |

| BS EN 12595 & BS 2000-319 | Bitumen and bituminous binders. Determination of kinematic viscosity |

| IP 319 | Bitumen and bituminous binders - Determination of kinematic viscosity aromatic hydrocarbon types in middle distillates - High performance liquid chromatography method with refractive index detection. |

| IP 226 | Petroleum products - Calculation of viscosity index from kinematic viscosity. |

Details

| Temperature range | Ambient to 150 °C |

|---|---|

| Temperature stability | ±0.02 up to and including 100 °C, ±0.03 above 100 °C |

| Tube capacity | Up to 10 |

| Bath fluid | Oil/silicone/water |

| Bath capacity | 40 Litres |

| Voltage | 220/240 V, 50 Hz |

| Power | 2.2 kW |

| Size (HxWxD) | 410 x 630 x 380 mm |

| Weight | 25 kg |

| CCCN Code | Tariff 90279000 |

Methods

Industries

Spares and accessories for KV-10 Viscometer Bath - 84300-0

Viscometer Tube Holder for CannonFenske - 23158-0

View accessory

Viscometer Tube Holder for U-tube Reverse Flow - 23159-0

View accessory

Viscometer Tube Holder for Ubbelohde & Suspended Level - 23157-0

View accessory

Viscometer Tube Cleaner - 97100-0

View product

Bench Viscometer Stand - 84008-0

View accessory

Digital Stopwatch - 22750-3

View accessory

Thermometer similar to ASTM127C: Low Haz with Works Certificate - ASTMST127C

View accessoryDownload product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.