Seta AvCount Particle Counters included in the New EN 590 Diesel Fuel Specification Update

The EN 590 Diesel Fuel Specification has been successfully balloted in response to concerns over poor fuel quality with a new particle limit of 10,000 particles per millilitre (<4 microns) now mandated. A new test method IP 630 will be included in EN 590 to be published in early 2025.

All automotive diesel fuel sold in European Union member states and other European countries must meet the new EN 590 standard and Seta AvCount particle counters are specified for the new mandated test. All automotive diesel that is manufactured outside the EU but is due to be shipped to a CEN member country must be tested using IP 630, where the AvCount product is specified.

‘point of import of EN 590 automotive diesel fuel into a CEN member country from a non-CEN member country, or, point of production of EN 590 automotive diesel fuel inside a CEN member country’.

The role of IP 630/24 in Fuel Quality

IP 630 was specifically developed to measure the number and size of particles in diesel fuel, addressing concerns related to soft particles and water content, both of which can significantly affect engine performance and longevity. The UK Energy Institute has updated the test method in support of the update to EN 590. IP 630/24 is designed to provide more accurate detection and removal of contaminants, contributing to better fuel quality overall.

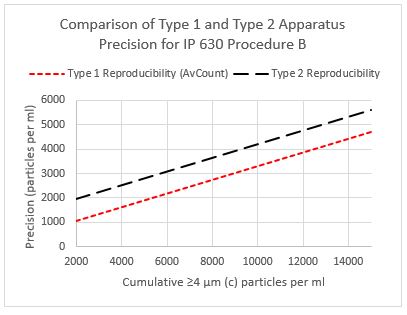

Testing Procedure B has been implemented, this procedure dissolves water and other soft particles and uses Type 1 (Seta AvCount particle counters) or Type 2 apparatus.

A comparison between Type 1 and Type 2 apparatus, determined Type 1 to have the best precision and use significantly less cleaning solvent, making Seta AvCount particle counters the preferred choice for ensuring compliance with the new diesel fuel standard, EN 590.

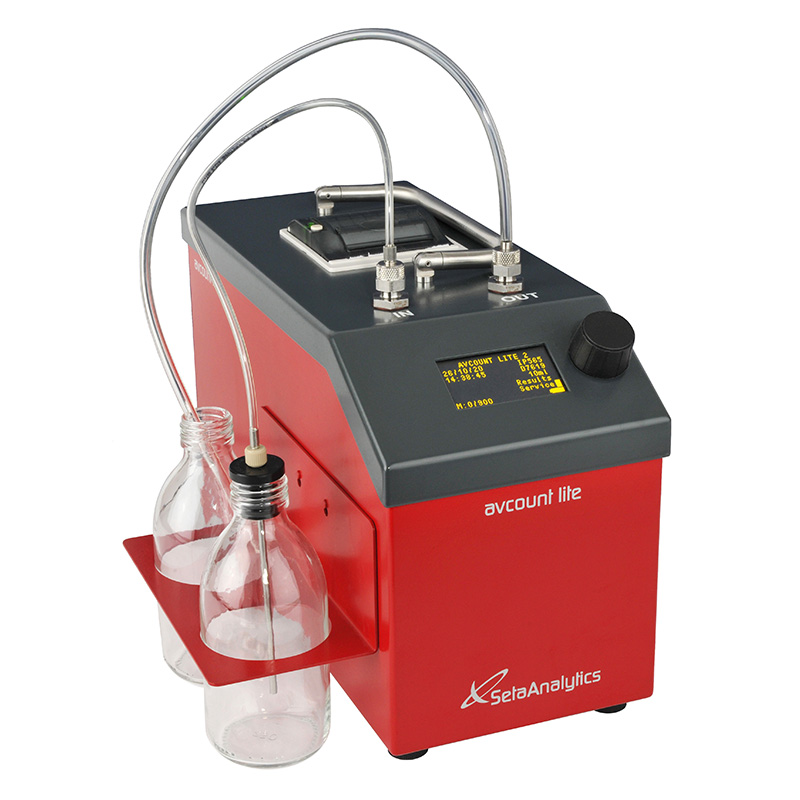

AvCount Particle Counters

AvCount particle counters are compact, bench-top instruments with an automated test process and simple user operation. A quick test time means less time for solids to settle out of the sample being tested, for more accurate results. An automatic test reduces operator time, giving laboratory users the option to work on something else, reducing labour costs.

AvCount particle counters use only a small amount of sample per test, helping to reduce costs and waste. Test results are displayed as ISO 4406 cleanliness codes and can be downloaded via LIMS, USB, QR code or printed via an internal printer, offering laboratories full flexibility.

All Seta particle counters are calibrated in accordance with ISO 11171, service and calibration can be completed in field, eliminating the time and cost associated with sending the instrument to a service centre.