Product

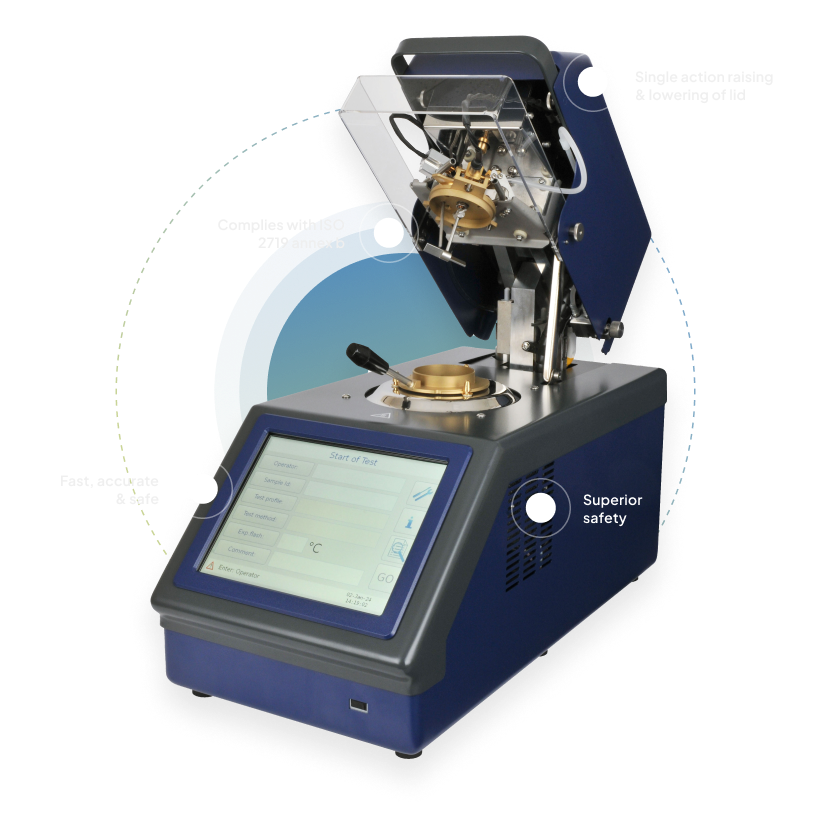

PM-93 Pensky-Martens Flash Point Tester - 35000-0

The Seta PM-93 is a fully automated Pensky-Martens closed cup flash point tester which combines strict method conformance with the latest control technology and safety systems to provide the ultimate level of fast, accurate and safe analysis.

You can determine flash points up to 400 °C using either standard mode for where the flash point is known or search mode for when it is not. Once complete, the PM-93 graphically displays results on the LCD screen. You can save results to the internal memory, email the results, export results to a USB, or transfer results via QR code.

SQC software analyses results, calculates mean, standard deviation, standard error and repeatability and plots results in accordance with ASTM D6299.

Learn more about flash point testing and which instrument you should be using >

Features

- Easy operation with touch screen

- Automatic flash point determination

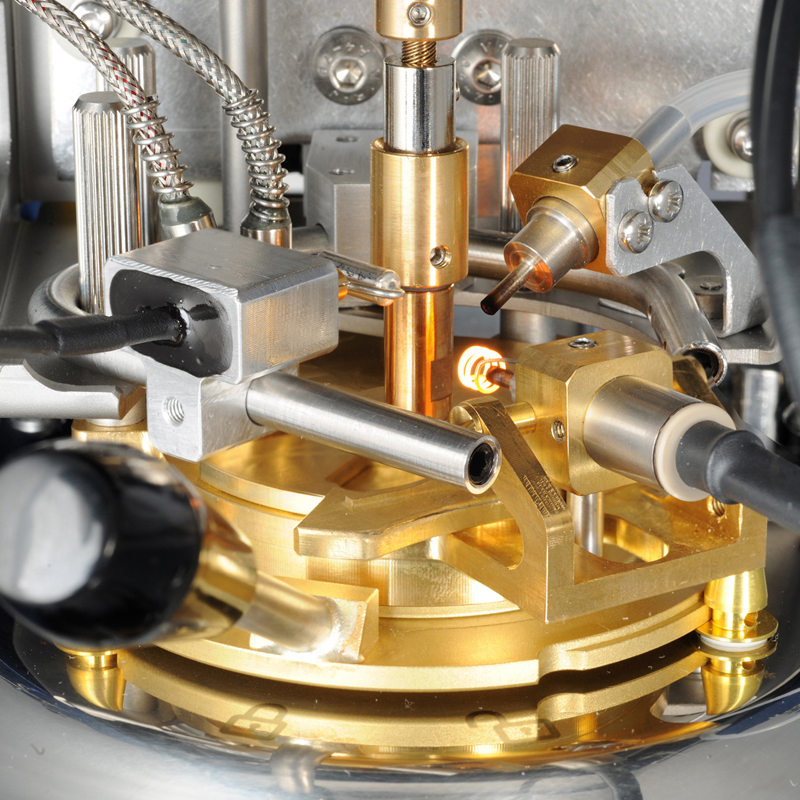

- Gas or electric ignition

- Patented 'SafeFlash' auto fire extinguisher

- Large capacity memory for storage of 30 test profiles, operator names and test methods

- Real time display of test progress and storage for 2000 results

- LIMS connectivity, results can be emailed, saved to USB or transferred via QR code

- Statistical Quality Control (SQC) software to analyse results to conform to ASTM D6299

Information

Details

Operator safety:Patented 'SafeFlash' fire extinguisher automatically activates in the event of excess flame or fire around test cup

PRT checks, safety dip before starting, over-temperature cut out, gas flame relight, gas shut off and emergency stop

Complies with ISO 2719 annex b

Ease of use:

Single action lifting arm operation

Intuitive user menu with colour touch screen

Fully automatic test procedure, little operator intervention required

Enhanced test throughput:

Unique test profiles to help improve efficiency when testing a large number of samples

Fast warm up and high capacity air cooling minimises cycle time

Precision and accuracy:

Automatic flash point ensures test repeatability

Results are corrected for variations in atmospheric pressure using the integral barometer

Unique alignment design ensures lid and cup locate perfectly

Password protected 'calibration' mode allows verification of instrument

SQC enhanced software to ensure precision and accuracy

Supplied with: Cup (fitted), Allen key (0.89 mm), Allen key (1.50 mm), mains cable, quick start guide and USB with the instrument handbook.

NOTE 1): The ‘SafeFlash’ fire extinguisher is a factory fit accessory and complies with ISO 2719. It must be ordered at the time of purchase or the unit must be returned to a service centre for installation. Comprises extinguisher, manifold assembly, regulator, fire sensor and remote operating button.

Details

| BS EN ISO 2719 & BS 2000-34 | Methods of test for petroleum and its products. Flash point by Pensky-Martens closed tester |

|---|---|

| ASTM D93 | Standard test methods for flash-point by Pensky-Martens closed cup tester |

| IP 34 | Determination of flash point - Pensky - Martens closed cup method (ISO 2719:2002) |

| ASTM D8175 | Standard Test Method for Finite Flash Point Determination of Liquid Wastes by Pensky-Martens Closed Cup Tester |

| SW-846 1010B | Test Methods for Flash Point by Pensky-Martens Closed Cup Tester |

Details

| Ignition system | Electric or gas |

|---|---|

| Flash detection | Thermal |

| Cooling | Forced air (integral fan) |

| Heating Rate | Fast heating rate (>10 °C/min) and standard; 5.5 °C/min; 3 °C/min; 1.3 °C/min; 1 °C/min |

| Temperature range | Ambient +5 °C to 400 °C |

| Internal Memory | 30 programmable test profiles, operator names, test methods and unlimited tests results |

| Fire Detection | Thermal with optional integral Fire Extinguisher |

| Size/Weight | 38.5 x 24 x 50 cm / 25 kg |

| Voltage | 230 Vac +/-15% or 110 Vac +/-15%. Frequency 50/60 Hz. Auto-sensing - no selector switch required |

| CCCN Code | Tariff 90268020 |

Methods

Industries

Spares and accessories for PM-93 Pensky-Martens Flash Point Tester - 35000-0

Pensky-Martens Certified Reference Material Low 100 ml (3 pack) - SETA-0412-0051

View accessory

Pensky-Martens Certified Reference Material Mid 100 ml (3 pack) - SETA-0412-0052

View accessory

Pensky-Martens Certified Reference Material High 100 ml (3 pack) - SETA-0412-0053

View accessory

Heat Sink Compound - 13740-017

View accessory

MTVM – Gas Oil 500 ml - 99851-0

View accessory

Dry Well Probe Calibrator - 60005-002

View accessory

Portable Digital Barometer - 99910-2

View accessory

Temperature Calibration Extension - 35000-012

View accessory

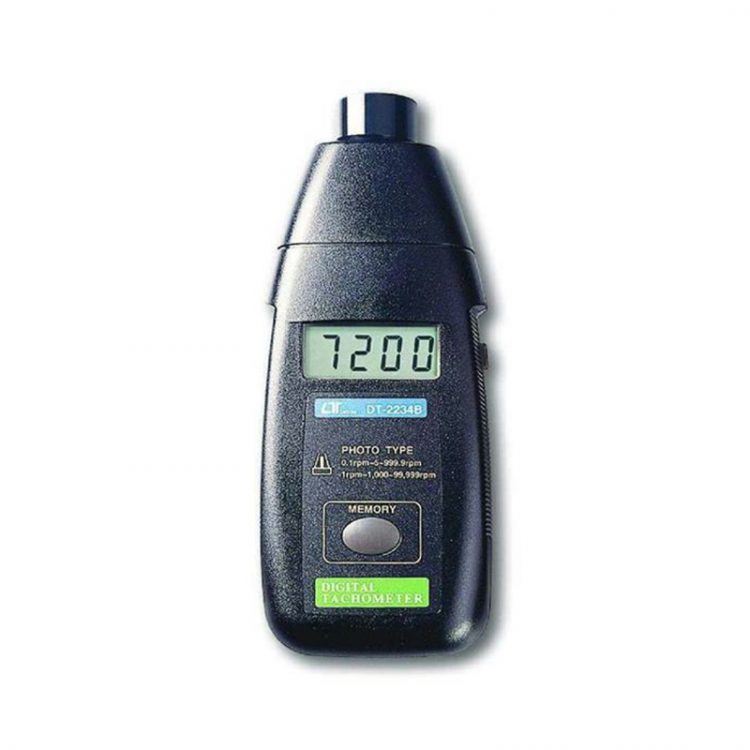

Digital Photo Tachometer - 99960-2

View accessory

Multi Test CRM – Gas Oil 500 ml - SP9000-0

View accessory

Thermometer Digital: -199 to 199 °C UKAS Calibrated - 82012-0

View accessory

MTVM – Fuel Oil 500 ml - 99852-0

View accessoryDownload product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.