Product

In-line Conductivity Sensor ATEX - 99500-0

The In-line Conductivity Sensor is an inline system that provides real time measurement of conductivity in pipelines using high accuracy AC measurement technology.

The system can be connected to a refinery/terminal management system to provide an automatic and continuous record of product conductivity levels, eliminating the requirement for manual sampling and record keeping. When installed with an automatic dosing system the in-line sensor allows automated additive dosing to maintain the conductivity within specified limits.

Learn more about in-line conductivity measurement

Read how Stanhope-Seta's conductivity sensors saved a refinery $100k per annum

Features

- In-line conductivity and temperature measurement conforming to ASTM D2624

- Conductivity range 0 to 2000 pS/m

- Accuracy +/-2% of reading

- Temperature range -40° to 85 °C +/-0.5°C

- Standard 16 bar max line pressure (high pressure model available)

- 4-20 mA output

- Stainless Steel construction

- ATEX, FM, IEC Certified (note - model dependent)

Information

Details

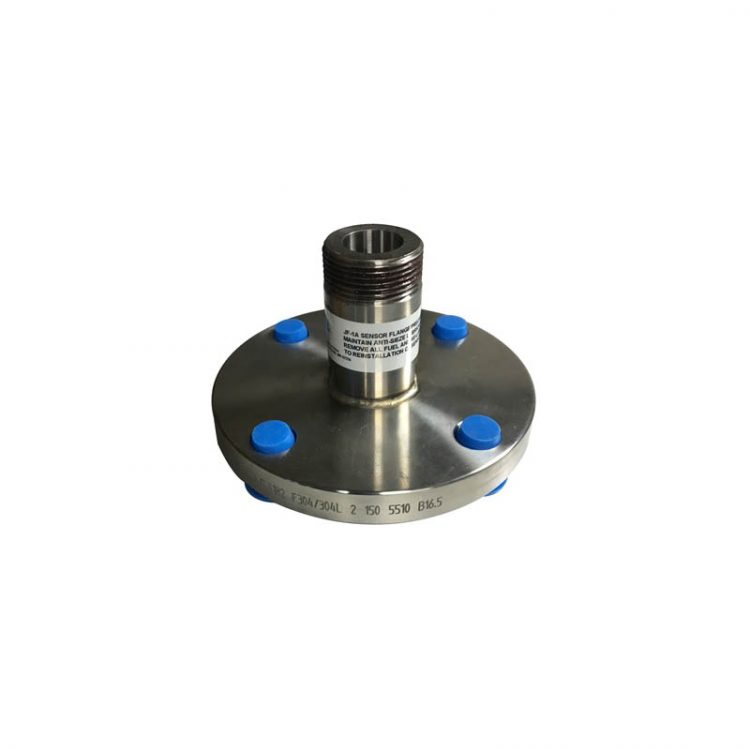

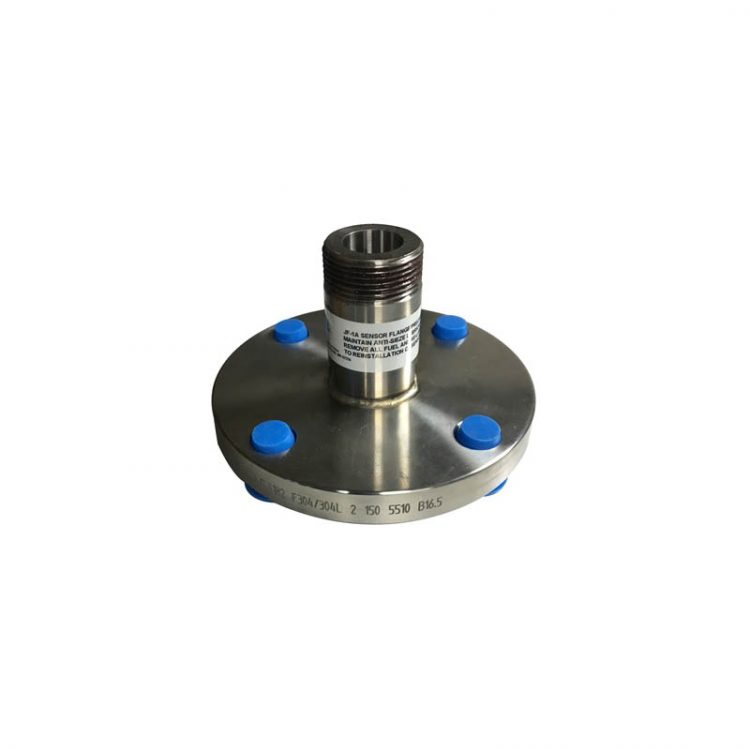

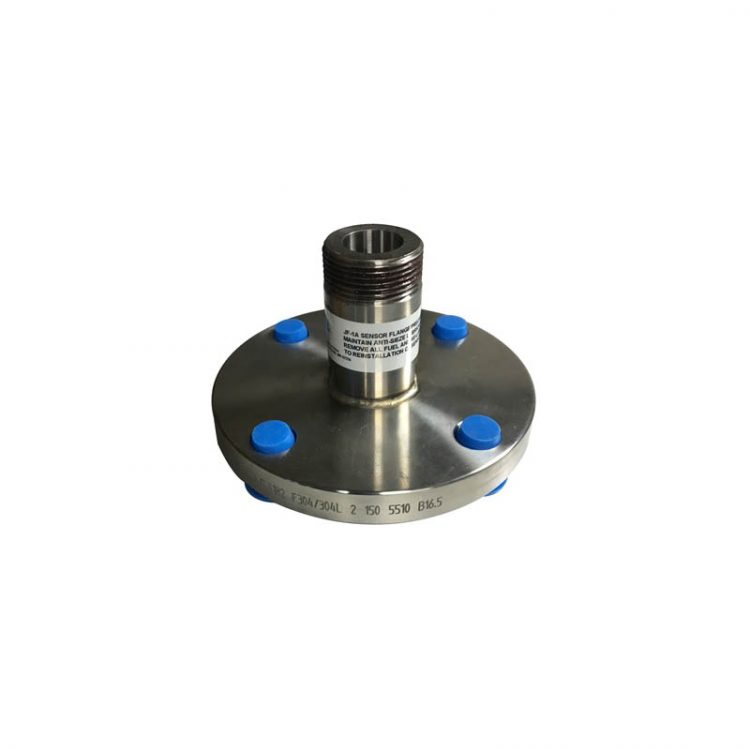

The conductivity sensor comprises two stainless steel coaxial electrode sensors and is suitable for long-term immersion in fuels. For maintenance the sensor is easily retracted from the fuel line through a full-port ball valve. The retractable fitting allows an adjustable insertion depth to optimize positioning of the sensor in the line and fitment to pipes of varying diameters.

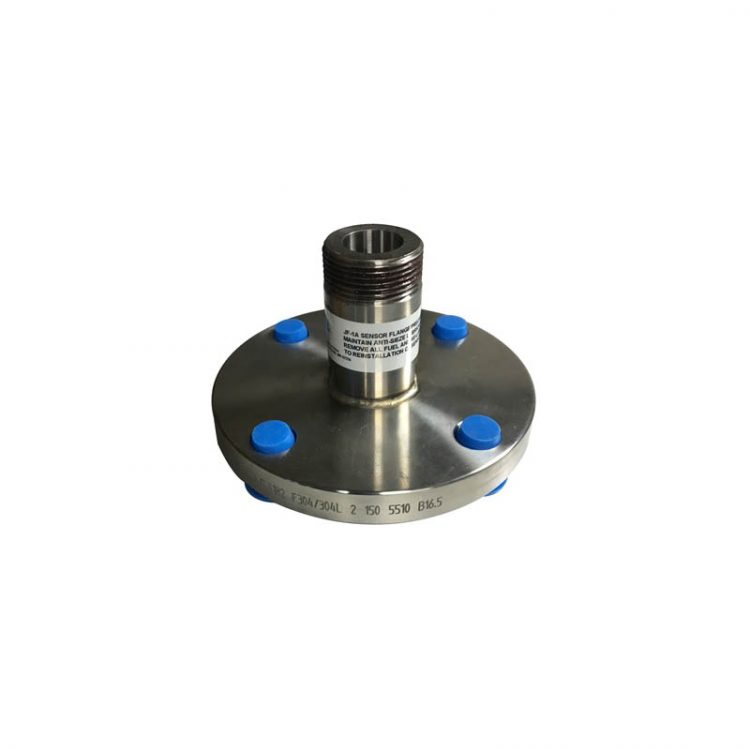

A typical mounting is via a 1” NPT pipeline nipple, and through a 1” Full port Ball Valve. The sensor connects directly to the Ball Valve using an adaptor. We recommend a suitable ball valve is sourced locally to suit pipe fittings. ANSI and DIN type Flange mounts are also available. Please select adaptor type from Accessories when ordering.

NOTE: Installation documents and schematics are available on request.

Details

| ASTM D2624 | Measurement of Electrical Conductivity of Distillate Fuels |

|---|---|

| IP 274 | Measurement of Electrical Conductivity of Distillate Fuels |

Details

| Range | 0 to 2000 pS/m |

|---|---|

| Accuracy | +/-2 pS/m (+/-2% of reading) |

| Pressure | 16 bar max pressure |

| Temperature Range | -40° to 85 °C, Accuracy +/-0.5 °C |

| Resolution | 0.1 pS/m |

| Sensor Type | 316 SS Coaxial Electrode |

| Calibration | Internal Source Zero and Scale |

| Certification | Ex II 2 G Ex db ia IIB+H2 T4 Gb |

| IP Rating | IP66 |

| CCCN Code | Tariff 90318080 |

Methods

Industries

Spares and accessories for In-line Conductivity Sensor ATEX - 99500-0

1″ANSI B16.5 300 Adaptor - 99517-0

View accessory

2″ DN50 PN25 Flange Adaptor - 99515-0

View accessory

3″ DN80 PN20 Flange Adaptor - 99516-0

View accessory

4″ANSI B16.5 150 Flange Adaptor - 99514-0

View accessory

3″ANSI B16.5 150 Flange Adaptor - 99513-0

View accessory

2″ANSI B16.5 300 Flange Adaptor - 99512-0

View accessory

2″ANSI B16.5 150 Flange Adaptor - 99511-0

View accessory

1″ NPT Adaptor for Ball Valve - 99510-0

View accessory

JF-1A Local Readout Display M20 Entry (ATEX) - 99508-0

View accessory

JF-1A USB Serial Test Cable - 99509-0

View accessory

JF-1A Local Readout Display (FM) - 99507-0

View accessory

1.5″ ANSI B16.5 150 Flange Adaptor - 99518-0

View accessoryDownload product profile

To view our full range of products, download our latest Product Profile here.

Want to know more?

View our full range of products, or simply get in contact with us for more information.